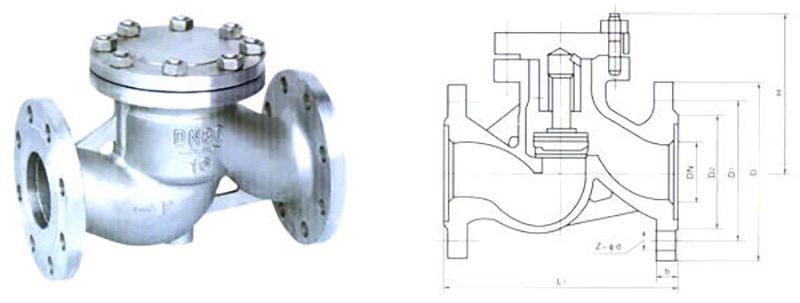

Lift Check Valve

Lift Check Valve

A check valve is a valve used in a pipeline system. Its main function is to prevent the backflow of the medium.

A check valve is a valve used in a pipeline system. Its main function is to prevent the backflow of the medium. It acts as a one-way valve in the pipeline, automatically or through external force to prevent the fluid from flowing back from the outlet of the pipeline to the inlet, ensuring that the fluid flows in the correct direction to avoid equipment damage, pollution or system failure.

※ Basic Structure

Valve body: The outer shell of the check valve, which serves to accommodate and protect the various internal parts.

Valve seat: The part of the valve body that contacts the valve disc, used to form a seal to prevent medium leakage.

Valve disc: Usually the core component of the check valve, responsible for opening or closing the valve according to the pressure changes of the fluid. The valve disc can be in various forms such as disc, ball, butterfly, etc.

Spring (optional): Used to help the valve disc close or ensure that the valve disc automatically closes when there is no fluid flow.

Sealing ring: Used to enhance the sealing between the valve seat and the valve disc to prevent leakage.

※ Product Application

Water treatment and water supply system

Prevent water backflow, ensure water quality, and avoid sewage or pollutants in the pipeline.

Oil and gas industry

Prevent oil and gas backflow, protect pipeline systems and pumps and other equipment.

HVAC system

Ensure that air or cooling water flows in the pipeline in a predetermined direction to avoid gas backflow or backflow of heat exchange media.

Fire protection system

In fire protection pipelines, check valves can effectively prevent water from flowing back into the pipeline network to ensure the effectiveness of the fire extinguishing system.

Chemical and pharmaceutical industries

Prevent media backflow, avoid cross-contamination between different chemicals, and ensure production safety and product quality.

※ Product Advantage

Prevent media backflow

The most significant advantage is that it can automatically prevent fluid from flowing back in the pipeline, protecting equipment from damage and avoiding system failure.

Automation

Most check valves do not require manual operation or external power, and automatically control opening and closing through fluid pressure, reducing manual maintenance.

Save energy and improve efficiency

By preventing backflow, energy waste is avoided, which plays an important role especially in water pumps and other equipment.

Enhance system stability

Check valves can ensure that the medium in the system flows in the correct direction, avoid reverse pressure in the system, and ensure the safe operation of the equipment.

Simple structure and easy maintenance

Check valves usually have a simple structure, long service life, and require little maintenance.

Adaptable

According to different requirements such as fluid medium, pipe diameter, pressure, etc., different types of check valves can be selected, such as lift type, ball type, butterfly type, etc., which have strong adaptability.

※ FAQ

What are the installation requirements for control valves?

The valve should be installed at the appropriate position of the pipeline to ensure that the flow direction is consistent with the direction indicated by the valve body; secondly, check whether the valve and its accessories are intact before installation to ensure that there is no damage; during installation, ensure that the pipeline connection is stable to avoid stress concentration and prevent damage to the valve; in addition, sufficient space should be provided for the valve to facilitate adjustment, inspection and maintenance; finally, the valve should be protected from excessive vibration or temperature, especially under high pressure and high temperature environments.

What are the common applications of temperature and pressure reducers?

Temperature and pressure reducers are widely used in many fields. They are mainly used in steam systems to reduce high-pressure steam to appropriate pressure to ensure safe operation of equipment. They are commonly used in power, fertilizer, food processing and other industries. They are also used in oil and gas pipelines, chemical production, pharmaceutical plants, etc. to ensure stable pipeline pressure and avoid system overpressure or excessive temperature. In addition, reducers are also used in HVAC, metallurgy and other industries to adjust the temperature and pressure of the fluid in the system to ensure the smooth progress of the process.

How to maintain medium and high pressure valves?

When maintaining medium and high pressure valves, first check the wear of key components such as valve body, valve seat, sealing ring and valve stem regularly. Clean the valve to prevent impurities from blocking and affecting operation. Check the operating performance of the valve to ensure flexible opening and closing without sticking. Check the sealing to prevent leakage and replace the seals if necessary. For valves that operate at high pressure for a long time, it is recommended to perform functional tests regularly to ensure their reliability under high pressure environment. In addition, check the connection parts of the valve to avoid looseness or leakage caused by vibration or corrosion.

※ Industry Applications

※ Company Introduction

Jiangsu Gaote Valve Industry Co., Ltd. was established in 2003. The company is a medium-sized enterprise specializing in the production of various petrochemical and power station valve series. The main products include high-temperature and high-pressure power station valves, gate valves, stop valves, ball valves, check valves, butterfly valves, instrument valves, needle valves, regulating valves and non-standard special valves for power stations, etc. Hundreds of varieties and specifications of valves, products are widely used in power, petrochemical, metallurgy, pharmaceutical, mining, steel, mining, water supply and drainage and other industries. The company's R&D team actively explores the field of valves and explores a path of industrial upgrading from ordinary valves to valves.

Jiangsu Gaote Valve Industry Co., Ltd. is an innovative demonstration enterprise of small and medium-sized enterprises in Jiangsu Province. It is located in the Economic Development Zone of Funing County, Jiangsu Province, and National Highway 204 passes through the territory. The company has passed the ISO9001 quality system certification and the special equipment manufacturing license of the People's Republic of China. It is a member unit of the power station accessories supply of the State Power Corporation, a member unit of the Sinopec Equipment Resources Market, and a member unit of the first-level supply network of China National Petroleum Corporation. It has gradually established a good reputation in power station valves. The company has an advanced management mechanism, with fixed assets of more than 30 million yuan, more than 100 sets of sophisticated mechanical processing equipment and inspection and testing equipment, and more than 10 technical R&D personnel, forming an integrated production, sales and service.